Abstract

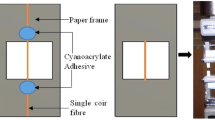

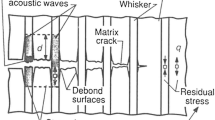

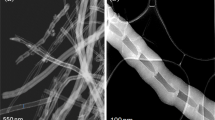

The mechanical and interfacial properties of single carbon fibres have been experimentally investigated. Longitudinal tensile strengths were determined using single filament as well as impregnated yarn specimens at various gauge lengths ranging from 5 to 200 mm. The tensile behaviour of the fibre depends on gauge length due to the presence of flaws along the fibre. Axial compressive strength was obtained by the tensile recoil method. The transverse modulus was measured by nano-indentation technique. Shear modulus was obtained by a torsional pendulum test. The apparent shear strength of carbon fibre/epoxy interface was characterised by a microbond fibre pull-out test. Data obtained in this work constitute important materials’ data input for the design and simulation of carbon fibre composite structures.

Similar content being viewed by others

References

Edison TA (1882) Manufacture of Carbon Filaments. US Patent 411,016

Ji XB, Khatri AM, Chia ESM et al (2013) Multi-scale simulation and FE-assisted computation of elastic properties of braided textile reinforced composites. J Compos Mater. doi:10.1177/0021998313480198

LLorca J, González C, Molina-Aldareguía JM, Segurado J et al (2011) Multiscale modeling of composite materials: a roadmap towards virtual testing. Adv Mater 23:5130–5147

Miravete A, Bielsa JM, Chiminelli A et al (2006) 3D mesomechanical analysis of three-axial braided composite materials. Compos Sci Technol 66:2954–2964

Ha SK, Jin KK, Huang Y (2008) Micro-Mechanics of Failure (MMF) for continuous fibre reinforced composites. J Compos Mater 42(18):1873–1895

Li X, Binienda W, Goldberg R (2011) Finite-element model for failure study of two-dimensional triaxially braided composite. J Aerospace Eng 24, special issue: Mechanics of Advanced Materials and Structures: 170–180

Kumari S, Nithya S, Padmavathi N et al (2010) Tensile properties and fracture behaviour of carbon fibre filament materials. J Mater Sci 45:192–200

Kumar S, Anderson DP, Crasto AS (1993) Carbon fibre compressive strength and its dependence on structure and morphology. J Mater Sci 28(2):423–439

Tsai CL, Daniel IM (1999) Determination of shear modulus of single fibres. Exp Mech 39:284–286

Lim J, Zheng JQ, Masters K, Chen WW (2010) Mechanical behavior of A265 single fibres. J Mater Sci 45:652–661

Miyagawa H, Mase T, Sato C et al (2006) Comparison of experimental and theoretical transverse elastic modulus of carbon fibres. Carbon 44:2002–2008

Rodríguez M, Molina-Aldareguía JM, González C, LLorca J (2012) A methodology to measure the interface shear strength by means of the fibre push-in test. Compos Sci Technol 72:1924–1932

Deteresa SJ, Farris RJ, Porter RS (1982) Behavior of an aramid fibre under uniform compression. Polym Compos 3(2):57–58

DeTeresa SJ, Allen SR, Farris RJ, Porter RS (1984) Compressive and torsional behaviour of Kevlar 49 fibre. J Mater Sci 19(1):52–72

DeTeresa SJ, Porter RS, Farris RJ (1985) A model for the compressive buckling of extended chain polymers. J Mater Sci 20(5):1645–1659

Maurin R, Davies P, Baral N, Baley C (2008) Transverse properties of carbon fibres by nano-indentation and micro-mechanics. Appl Compos Mater 15:61–73

Ueda M, Takiguchi T (1991) Measurement of transverse Young’s modulus of fibres by angular characteristics of ultrasonic scattering. Adv Compos Mater 1(4):309–320

Sun XS, Tan VBC, Tay TE (2011) Micromechanics-based progressive failure analysis of fibre-reinforced composites with non-iterative element-failure method. Comput Struct 89(11–12):1103–1116

Li X (2010) Mesomechanical model for failure study of two dimensional triaxial braided composite materials, PhD Dissertation, The University of Akron

Bacarreza O, Aliabadi MH, Apicella A (2012) Multi-scale failure analysis of plain-woven composites. J Strain Anal Eng 47(6):379–388

Gibson RF (1994) Principles of composite materials mechanics. McGraw-Hill, New York

Swift C (2012) Specialty Fibers: Technologies and Global Markets. Market Research Report, BCC Research

Weibull W (1939) A statistical theory of the strength of materials. Ing Vetenskaps Akad Handl 151:5

van der Zwaag S (1989) The concept of filament strength and the Weibull modulus. J Test Eval 17(5):292–298

Waterbury MC, Drzal LT (1991) On the determination of fiber strengths by in-situ fiber strength testing. Compos Sci Technol Res 13:22–28

Reynolds WN, Sharp JV (1974) Crystal shear limit to carbon fibre strength. Carbon 12:103–110

Zohdi TI, Powell D (2006) Multiscale construction and large-scale simulation of structural fabric undergoing ballistic impact. Comput Method Appl Mech 195:94–109

Macturk KS, Eby RK, Adams WW (1991) Characterization of compressive properties of high-performance polymer fibres with a new microcompression apparatus. Polymer 32(10):1782–1787

Sinclair D (1950) A bending method for measurement of the tensile strength and Young’s modulus of glass fibres. J Appl Phys 21:380–386

Hawthorne HW, Teghtsoonian E (1975) Axial compression fracture in carbon fibres. J Mater Sci 10(1):41–51

Oya N, Johnson DJ (2001) Longitudinal compressive behaviour and microstructure of PAN-based carbon fibres. Carbon 39(5):635–645

Allen SR (1987) Tensile recoil measurement of compressive strength for polymeric high performance fibres. J Mater Sci 22:853–859

Kumar IP, Mohite PM, Kamle S (2013) Axial compressive strength testing of single carbon fibres. Arch Mech 65(1):27–43

Jiang H, Abhiraman AS, Tsui K (1993) Analysis of failure in ‘recoil from tension’ of pan-based carbon fibres. Carbon 31(6):887–894

Chung DDL (1994) Carbon fibre composites. Butterworth-Heinemann, Boston

Northolt MG, Veldhuizen LH, Jansen H (1991) Tensile deformation of carbon fibres and the relationship with the modulus for shear between the basal planes. Carbon 29(8):1267–1279

Dobb MG, Johnson DJ, Park CR (1990) Compressional behavior of Carbon Fibers. J Mater Sci 25(2):829–834

Oya N, Johnson DJ (1999) Direct measurement of longitudinal compressive strength in carbon fibres. Carbon 37(10):1539–1544

Agilent Technologies (2013) Agilent Nano Indenter G200, http://cp.literature.agilent.com/litweb/pdf/5990-4172EN.pdf. Accessed 22 Jan 2014

Molazemhosseini A, Tourani H, Naimi-Jamal MR, Khavandi A (2013) Nanoindentation and nanoscratching responses of PEEK based hybrid composites reinforced with short carbon fibres and nano-silica. Polym Test 32:525–534

Tsujikami T, Horikawa T, Hirosawa S, Zako M (2006) Approach to analysis of mechanical behavior of textile composites by inclusion element method. JSME Int J A Mech M 49(3):418–425

Choi NS, Park JE, Kang SK (2009) Quasi-disk type microbond pull-out test for evaluating fibre/matrix adhesion in composites. J Compos Mater 43:1663–1677

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ji, X., Wang, C., Francis, B.A.P. et al. Mechanical and Interfacial Properties Characterisation of Single Carbon Fibres for Composite Applications. Exp Mech 55, 1057–1065 (2015). https://doi.org/10.1007/s11340-015-0007-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11340-015-0007-3